Overview of TB-3535P full-automatic brush type PCBA single-sided cleaner

The equipment uses the transfer progressive and manipulator grasping technology to apply the touch brush method to the residual flux on the PCBA wave peak welding surface

With volatile solvent cleaning agent, multiple cleaning processes can be carried out, with high cleaning cleanliness, good equipment safety and perfect

Replace manual work and greatly improve cleaning efficiency.

Equipment features:

? This equipment is specially designed for computer motherboards, video cards, power boards and other products. It is used to clean one side of soldering flux after wave soldering instead of manual brushing

Cleaning, improve cleaning capacity and cleanliness, and reduce cleaning costs;

? The equipment perfectly combines the automatic manipulator grasping technology and efficient brushing technology;

? Revolutionary change has been made to the traditional solvent manual cleaning mode, and the full automatic cleaning mode has avoided the intimacy of operators

Contact with chemical liquid;

? After multiple brushing processes, the residual flux on the PCBA after welding can be effectively removed without wetting the front components;

? The unique rolling brush disc brush combination cleans from multiple directions, completely eliminating the dead angle of cleaning, and fully ensuring the cleanliness of cleaning.

Even the most stubborn hand welding spot residues can be completely removed at one time;

PCBA with maximum washable width of 350mm;

? The equipment adopts humanized design, which is convenient to disassemble and assemble the roller brush, and can quickly realize cleaning and replacement;

Seamless and compatible with online continuous plate feeding and offline manual plate placing, two feeding modes;

? Mechanical hand pressure and torque monitoring design, PCBA deformation and stress can be controlled, and can automatically compensate for high brushing surface caused by brush wear

Degree drop;

The induction design of blanking and stacking. If the equipment in the rear section is down, the equipment will automatically switch to the waiting mode to avoid stacking;

? The design of liquid loading and circulating filtration and diversion of cleaning liquid shall keep the liquid clean at all times and keep the brushing effect consistent;

? The transportation speed and brushing frequency can be adjusted steplessly to easily control the cleaning process;

? Visual observation window, with clear process flow;

Full automatic online cleaning can be realized after wave soldering.

2、 TB-3535P full-automatic touch brush PCBA single-sided cleaning machine technical specifications

1. Name: full-automatic solvent brush PCBA single-sided cleaner

2. Product model: TB-3535P

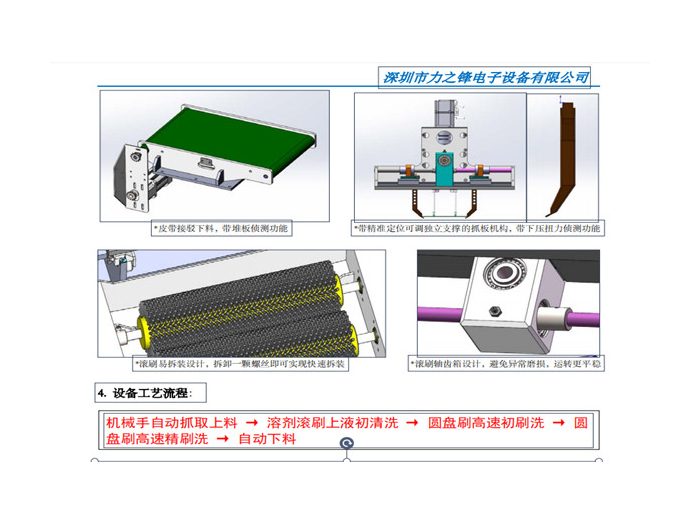

3. Design details:

4. Equipment process flow:

5. Main functional systems and parameters of the product:

5.1 Overall equipment overview:

? The equipment is mainly controlled by manipulator grabbing system, transfer progressive system, brush cleaning system, circulating filtering system and electrical appliances

System and other institutional components. Each part is designed as an independent module, which is easy to operate and maintain;

? This equipment is a cleaning machine specially designed for the removal of soldering flux after wave soldering, which adopts online full-automatic brushing mode;

Track width and brushing speed can be adjusted, and the width of card mountable PCB board: 70~350mm, which can be connected to wave soldering to realize

Fully automatic online cleaning;

Brushing speed: 12~20s/pcs, which can be adjusted according to the actual brushing effect;

Cardable PCB board thickness: 1~3mm, total height ≤ 80mm.

5.2 Body:

? Boundary dimension: 2600mm(

L)× 1200mm(W)× 1700mm(H)

? Height of operating surface: 750mm

? Material: SUS304 stainless steel special aluminum frame

Total weight of equipment: about 620Kg

Manipulator automatically grabs and loads materials → solvent roller brush for initial cleaning → disc brush for initial cleaning at high speed → round

High speed fine brushing of disc brush → automatic blanking

5. Main functional systems and parameters of the product:

5.1 Overall equipment overview:

? The equipment is mainly controlled by manipulator grabbing system, transfer progressive system, brush cleaning system, circulating filtering system and electrical appliances

System and other institutional components. Each part is designed as an independent module, which is easy to operate and maintain;

? This equipment is a cleaning machine specially designed for the removal of soldering flux after wave soldering, which adopts online full-automatic brushing mode;

Track width and brushing speed can be adjusted, and the width of card mountable PCB board: 70~350mm, which can be connected to wave soldering to realize

Fully automatic online cleaning;

Brushing speed: 12~20s/pcs, which can be adjusted according to the actual brushing effect;

Cardable PCB board thickness: 1~3mm, total height ≤ 80mm.

5.2 Body:

? Boundary dimension: 2600mm(

L)× 1200mm(W)× 1700mm(H)

? Height of operating surface: 750mm

? Material: SUS304 stainless steel special aluminum frame

Total weight of equipment: about 620Kg

Body structure description: the whole machine is a closed structure, and the frame is formed by special aluminum profiles; SUS304 is used for outer sealing plate and upper cover

Stainless steel plate; The cleaning tank is made of SUS304 stainless steel plate; The observation window and equipment are of integral structure, which are corrosion resistant, durable and beautiful

Fang. A movable door is reserved in front of the machine body to facilitate equipment maintenance.

5.3 Brushing station:

? Cleaning medium: environment-friendly solvent cleaner without flash point or high flash point

Brush wire material: anti-static special nylon wire (3 roller brushes and 2 disc brushes)

? Number of liquid storage tanks: 1

? Volume of liquid storage tank: 40L

? Filtering precision: 5 μ m

Brushing station description: the equipment is divided into three brushing stations, and the roller brush and disc brush are combined to drive the cleaning liquid to moisten through automatic liquid feeding

The wet brush and the liquid brush drive the cleaning liquid to wet the surface of PCBA base plate through the relative movement of contact with the plate surface

Wet and brush to dissolve and separate the dirt on the surface. The pollutants are filtered by the filtering system along with the cleaning solution, which can be recycled to

Use.

5.4 Level control device:

Because of the volatilization of solvent and the repeated entry and exit of the washed workpiece into the cleaning tank, the solvent will inevitably be brought out, which will cause

Because of the natural loss of solvent, liquid level controller is installed in the corresponding liquid storage tank of each scrubbing tank. When the liquid level drops to a low level

When the liquid level warning line is set, the liquid level controller will send an alarm signal to prompt manual liquid replenishment.

5.5 Electrical control system:

? Operation mode: the equipment operates in automatic mode with perfect protection functions (high and low liquid level protection, downforce

Monitoring, stacking alarm, motor overload alarm, etc.);

The electric control system is installed in the power supply cabinet, and the centralized control mode is adopted. The power supply cabinet is isolated from the equipment, and the control is independent

Besides convenience, it also ensures safety.

6. Main technical specifications and parameters:

Total power of equipment<6KW

Input voltage: 380V AC, 50Hz

Overall dimension of the whole set of equipment 2600mm(

L)× 1200mm(W)× 1700mm(H)

Operation surface height is about 750mm

Total weight of equipment is about 620kg

3、 Equipment installation

1. Equipment foundation

Space shall be reserved around the equipment to facilitate personnel operation. The back edge of the equipment shall be at least 500mm away from the wall.

2. Common medium conditions

Power supply voltage: AC380V

Voltage fluctuation range: 220V± 10%

Frequency and fluctuation range: 50Hz± 1Hz

3. Technical requirements for installation

The power supply is 380V to ensure the balance of the equipment, and the equipment must be reliably grounded.

4. Mechanical installation and commissioning

A. Adjust the equipment according to the sequence of process flow to make it straight and horizontal; Shenzhen Lizhifeng Electronic Equipment Co., Ltd

SHENZHEN LEADFREE ELECTRONIC EQUIPMENT CO., LTD

Address: Building A, Shifeng Science Park, No. 1, Datian Yangnan 1st Road, Songgang Street, Bao'an District, Shenzhen

Tel.: 86 755 29894111

B Connect the power supply and other public media according to the technical requirements;

C Add a proper amount of cleaning liquid into the cleaning tank, close the main switch of the equipment, and turn on the circulating pumps one by one to check whether the rotation direction of the motor is consistent with the mark

Same. Note: Before starting the pump, the outlet valve must be opened to the full opening position to prevent the pump from holding;

D After the above commissioning, no-load test run can be carried out, and the no-load test run time shall not be less than 60 minutes;

E. After the no-load test run is qualified, adjust the infusion flow, transfer speed, brushing height and brush speed according to the process requirements

Carry out load commissioning, and put it into trial production after the quality meets the requirements.

5. Electrical installation

The electrical connection must be carried out after the power switch of the distribution box is turned off. Please connect the wires in the correct way according to the wiring diagram to ensure a firm connection

Gu.

4、 Adjustment and use

1. Before starting each time, please check whether the power supply meets the equipment requirements. If it exceeds the specified range (220V± 10%), it is forbidden to turn it on

The machine can only be started when the power supply meets the requirements.

2. Before starting each time, please check whether the liquid level in the cleaning tank is normal. If the liquid level is not enough, do not start the machine. After adding detergent

Restart.

5、 Hoisting, transportation and packaging of equipment

1. On the premise of ensuring the safe transportation of equipment, the equipment shall be manufactured and transported as a whole as far as possible;

2. The equipment shall be transported according to the normal working condition, and the upside down or tilt shall be avoided as far as possible;

3. The moving parts of the equipment, such as carriers, tank covers, must be temporarily fixed;

4. The equipment packed shall be hoisted and unloaded with ropes tied according to the lifting marks on the packing box, and shall be stable without excessive inclination;

5. When lifting the equipment during unloading, wooden blocks shall be placed at the contact part of the rope to avoid damaging the surface of the washer.

6、 Technical services

1. Warranty period: one year free warranty from the date of final acceptance of the equipment;

2. Service scope: In case of equipment failure within the warranty period, the Supplier shall repair and replace spare parts for the Demander free of charge;

3. Service response time: 2 hours;

4. Service resolution time: 1-2 days.

7、 Precautions:

1. The equipment is electrically driven. In principle, it is prohibited to use low flash point flammable and explosive cleaning solvents. The equipment installation position shall be

Set an independent space away from fire sources, install exhaust devices, and take fire and explosion prevention measures.

2. Our company will not bear any responsibility for any harm caused by the use of low flash point flammable solvent

Fully automatic online cleaning;

Brushing speed: 12~20s/pcs, which can be adjusted according to the actual brushing effect;

Cardable PCB board thickness: 1~3mm, total height ≤ 80mm.

5.2 Body:

? Boundary dimension: 2600mm(

L)× 1200mm(W)× 1700mm(H)

? Height of operating surface: 750mm

? Material: SUS304 stainless steel special aluminum frame

Total weight of equipment: about 620Kg